CNC (Computer Numerical Control) machines are a backbone of modern manufacturing. They provide precision, automation, and consistency in fabricating complex components from metal, plastic, wood, and composites. One of the fundamental characteristics that define a CNC machine’s capabilities is the number of axes it operates on. From simple 2-axis systems to sophisticated 9-axis machines, each additional axis adds a new dimension of motion and complexity, allowing manufacturers to achieve more intricate and refined operations.

CNC Axes: The Basics

What Is an Axis in CNC Terminology?

In CNC machining, an axis refers to a direction along which the cutting tool or workpiece moves. These directions can be linear (straight lines) or rotary (circular paths). Each axis gives the machine a degree of freedom. The more axes a CNC machine has, the more versatile and capable it becomes in shaping parts.

Cartesian Coordinate System in CNC

CNC machines rely on the Cartesian coordinate system to define movement. In this system:

- The X-axis represents left-to-right movement.

- The Y-axis represents front-to-back movement.

- The Z-axis represents up-and-down movement.

Most CNC machines start with these three linear axes and build upon them by adding rotary axes for increased flexibility.

Classification by Number of Axes

2-Axis CNC Machines

Functionality and Motion

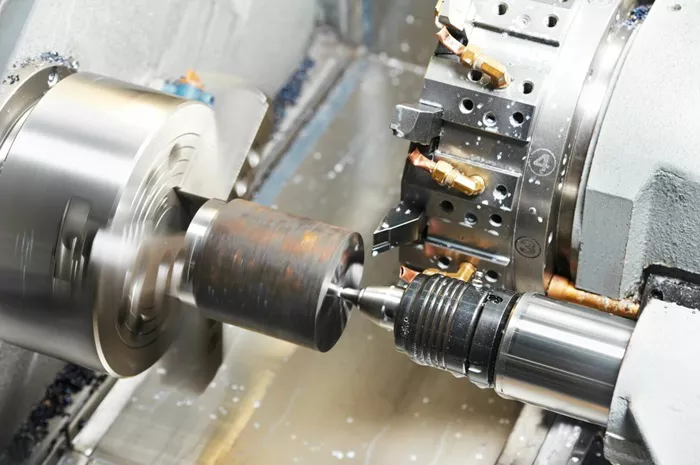

A 2-axis CNC machine operates along the X and Z axes. These machines are typically used for basic turning operations on a lathe, where the workpiece rotates while a cutting tool moves in two directions to remove material.

- Common Applications

- Cylindrical parts

- Bushings

- Shafts

- Basic turning jobs

2-axis machines are ideal for producing symmetrical parts and are often found in entry-level CNC setups or traditional manufacturing environments.

3-Axis CNC Machines

The Standard CNC Milling Setup

The 3-axis CNC machine adds the Y-axis to the basic 2-axis configuration, enabling movement along X, Y, and Z. This is the most common configuration and allows for cutting along three perpendicular directions.

- Capabilities

- Drilling

- Milling

- Engraving

- Profile cutting

While 3-axis machines can produce complex geometries, they often require multiple setups to access all sides of the part.

Limitations

- Difficult to machine undercuts and deep cavities

- Requires manual repositioning for features on different faces

Despite limitations, 3-axis machines are widely used in prototyping and general manufacturing.

4-Axis CNC Machines

Introduction of Rotary Motion

In a 4-axis CNC machine, a rotary axis is added—typically called the A-axis. This allows the workpiece to rotate around the X-axis while the tool moves in X, Y, and Z directions.

Advantages

- Ability to machine around a cylinder

- Eliminates the need for multiple setups

- Improved precision for parts requiring side features

Typical Uses

- Engraving on cylindrical surfaces

- Drilling holes at specific angles

- Producing gear teeth or helical grooves

This added axis enhances productivity and accuracy for more complex parts.

5-Axis CNC Machines

Two Rotary Axes for Full Flexibility

5-axis CNC machines include two rotary axes, typically designated as A and B (or A and C). These machines can rotate both the workpiece and the tool, providing unprecedented access to all sides of a part.

Advantages of 5-Axis Machining

- Complete parts in one setup

- Machine complex geometries with ease

- Higher surface finish and precision

- Reduced tool wear due to optimal angles

Key Applications

- Aerospace components

- Medical implants

- Automotive molds and dies

- Sculptural or artistic designs

5-axis machines are a standard in industries where complex, high-precision parts are essential.

6-Axis CNC Machines

Adding a Moving Head or Table

A 6-axis CNC machine adds an additional rotary or linear motion, allowing even greater flexibility. Often, it involves a robotic head that can move in a swiveling pattern or a rotating work table that adds dynamic functionality.

Performance Benefits

- Ultra-fast production times

- Even more tool orientation control

- Seamless transitions across features

Specialized Uses

- Advanced aerospace design

- Robotic milling and trimming

- 3D surfacing of irregular parts

6-axis CNC machines blur the line between machining and robotic automation.

7-Axis CNC Machines

Complex Part Production in One Cycle

A 7-axis CNC machine includes three linear axes and four rotary axes. These machines can work simultaneously on different features of a part without repositioning or transferring.

Benefits

- Machine multiple sides without delay

- Enables tools to approach parts from any direction

- Supports high-mix, low-volume production

Applications

- Tube bending

- Full-contour sculpting

- Custom orthopedic components

Although expensive, 7-axis machines drastically reduce lead times and labor costs for complex part production.

8-Axis CNC Machines

Unmatched Precision and Versatility

An 8-axis CNC machine further increases control by offering additional simultaneous movements. It might include dual spindles, multiple tool turrets, or robotic arms for handling.

Capabilities

- Produce intricate details from any orientation

- Reduce downtime between setups

- Combine turning and milling operations seamlessly

Common Use Cases

- Watchmaking

- Microcomponent manufacturing

- High-end custom parts

8-axis machines are typically used by manufacturers who require ultra-precision in demanding industries.

9-Axis CNC Machines

The Pinnacle of CNC Technology

The 9-axis CNC machine combines three linear axes and six rotary axes, often featuring two rotating spindles and multiple tool turrets. This allows for multiple simultaneous operations.

Key Features

- Perform operations on different parts of a component at once

- Near-zero need for secondary operations

- Ideal for small, intricate, or asymmetrical parts

Industrial Applications

- Swiss-type lathe systems for miniature components

- Watch and jewelry fabrication

- High-precision electronic parts

Despite the cost and complexity, 9-axis machines are valuable for cutting-edge applications where tolerances are extremely tight.

Why Axis Count Matters

Greater Axes Mean More Control

Each additional axis provides more control over the toolpath. This allows more complex and intricate parts to be machined efficiently, often in a single setup. More axes reduce the number of fixtures, manual interventions, and setup time.

Increased Cost and Learning Curve

With more axes comes greater cost—not only for the machine but also for programming, maintenance, and training. Advanced multi-axis machines require skilled operators and sophisticated CAM (Computer-Aided Manufacturing) software.

Choosing the Right Number of Axes

When deciding which CNC machine to use or purchase, consider:

- Complexity of parts

- Production volume

- Budget

- Available operator skill level

- Need for automation

3-axis machines suffice for most general-purpose jobs. However, for aerospace, medical, or artistic applications, 5-axis and beyond are often necessary.

Conclusion

CNC machines have revolutionized the way we manufacture products, and the number of axes they operate on is a direct measure of their capability and sophistication. From simple 2-axis lathes to advanced 9-axis Swiss machines, each level serves a unique purpose in modern fabrication.

Understanding how many axes a CNC machine has—and what those axes do—is essential for engineers, machinists, and manufacturers looking to optimize productivity and meet the demands of increasingly complex designs. Whether you’re creating a simple bracket or a complex turbine blade, the right CNC machine with the appropriate number of axes is key to achieving precision, efficiency, and quality.

By mastering the capabilities of each axis level, businesses can invest wisely and push the boundaries of what’s possible in modern machining.