Computer Numerical Control (CNC) machines have revolutionized modern manufacturing. These machines use computer programming to control tools that cut, shape, drill, and mill materials with high precision. CNC technology has allowed manufacturers to produce complex parts faster, more accurately, and more consistently than ever before.

From intricate aerospace components to custom wooden furniture, CNC machines can create a wide range of products. In this article, we will explore in detail what you can make with a CNC machine, the types of CNC machines available, materials that can be machined, and the many industries that rely on CNC machining every day.

Understanding CNC Technology

CNC machines operate through numerical control, where a computer program dictates the movements of the machine. The instructions, written in a language called G-code, tell the machine exactly how to move and what to do. These machines can work with a wide variety of tools, such as drills, mills, routers, lathes, lasers, and plasma cutters.

The key advantage of CNC is automation. Once programmed, a CNC machine can produce hundreds or thousands of identical parts with minimal human intervention, greatly increasing efficiency and consistency in production.

Types of CNC Machines

There are many types of CNC machines, each with unique capabilities. Understanding the differences helps identify what each machine can create.

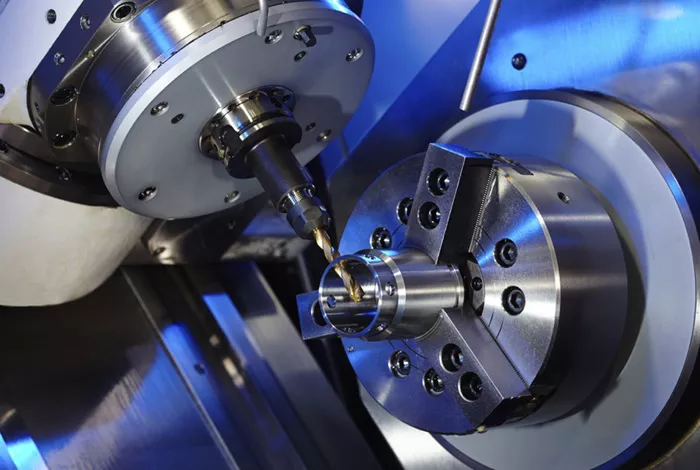

CNC Milling Machines

CNC milling machines use rotary cutting tools to remove material. They can move along multiple axes to produce complex shapes. These machines are used to make engine components, housings, metal brackets, and molds. Milling is one of the most versatile CNC processes.

CNC Lathes

A CNC lathe rotates the material while a fixed cutting tool shapes it. This method is perfect for producing symmetrical parts such as shafts, bushings, rings, and pulleys. CNC lathes are widely used in automotive, aerospace, and medical manufacturing.

CNC Routers

CNC routers are primarily used to cut wood, plastic, and foam. They are commonly used in woodworking, cabinetry, signage, and model making. CNC routers can cut intricate patterns and create three-dimensional designs in soft materials.

CNC Plasma Cutters

These machines use a high-temperature plasma arc to cut through metals like steel, aluminum, and copper. They are fast and effective for sheet metal work, making them ideal for custom automotive and industrial applications.

CNC Laser Cutters

Laser cutters use a focused laser beam to cut or engrave materials. They are capable of extremely fine detail, making them suitable for jewelry, electronics, and decorative items. Lasers can work with metals, plastics, glass, and wood.

CNC EDM (Electrical Discharge Machining)

EDM removes material using electrical sparks. It is used to machine hard metals and produce intricate shapes that traditional tools cannot handle. EDM is commonly used in mold making, aerospace, and precision tool industries.

Materials You Can Machine

CNC machines are capable of working with a broad range of materials, each requiring different tools and speeds.

Metals

CNC machining is highly effective for metals such as aluminum, brass, copper, stainless steel, titanium, and tool steel. These materials are used in aerospace, automotive, military, and industrial applications. Machined metal parts include gears, pistons, frames, valves, and structural components.

Plastics

CNC machines can shape various plastics like ABS, nylon, polycarbonate, PVC, and acrylic. Plastics are lighter and cheaper than metals, making them ideal for electronic housings, automotive parts, consumer products, and packaging components.

Wood

Woodworking with CNC routers allows artisans and manufacturers to create detailed furniture, cabinetry, doors, and décor items. Both hardwoods and softwoods can be machined, including oak, maple, pine, and cherry.

Foam

Foam is used for packaging, modeling, and insulation. CNC machines can carve foam into precise shapes, often for custom packaging inserts, prototypes, and architectural models.

Composites

Carbon fiber, fiberglass, and other composites are used in aerospace and performance automotive industries. CNC machines carefully cut these materials to produce lightweight, strong components.

What You Can Make with a CNC Machine

The versatility of CNC machines makes them suitable for producing a wide variety of products and parts. Below are categories and examples of what can be made.

Mechanical Parts and Components

CNC machining is ideal for making high-precision mechanical components used in engines, machines, tools, and industrial systems. Common examples include:

- Gears and gearboxes

- Bearings and housings

- Brackets and fasteners

- Hydraulic and pneumatic parts

- Couplings and adapters

Custom Tools and Fixtures

CNC machines can produce specialized tools and fixtures for use in other manufacturing processes. These include:

- Jigs and fixtures for assembly lines

- Custom cutting tools and dies

- Injection mold cavities

- Inspection and measurement tools

Automotive Components

In the automotive industry, CNC machining is used for both production and customization. You can make:

- Engine blocks and cylinder heads

- Suspension arms and control arms

- Custom wheels and calipers

- Dashboards and instrument panels

- Transmission components

Aerospace Parts

Aircraft components require tight tolerances and high-strength materials. CNC machines can produce:

- Wing spars and ribs

- Landing gear assemblies

- Avionics enclosures

- Heat shields

- Engine mount brackets

Medical Devices

Medical-grade CNC machining produces parts for diagnostics, surgery, and prosthetics. Examples include:

- Orthopedic implants

- Dental crowns and bridges

- Joint replacements

- Custom surgical instruments

- Housings for medical electronics

Consumer Products

Many everyday items can be produced using CNC machining, including:

- Smartphone enclosures

- Laptop chassis

- Headphone components

- Eyewear frames

- Kitchen gadgets

Furniture and Interior Design

CNC routers are widely used in furniture making and architectural elements. You can create:

- Tables, chairs, and shelves

- Cabinet doors and drawers

- Wall panels and trim

- Decorative screens

- Custom wood carvings

Signage and Artwork

Businesses and artists use CNC machines for custom signage and art installations. Projects include:

- Business signs

- Logos and branding displays

- Wall art and sculptures

- Laser-engraved designs

- Custom trophies and awards

Prototypes and R&D Projects

CNC machining is invaluable in product development. Engineers and designers can quickly create functional prototypes for testing. These can include:

- Electronic device prototypes

- Mechanical product enclosures

- 3D models for concept validation

- Test fixtures for quality control

DIY Projects and Hobbies

Hobbyists and makers use desktop CNC machines to create unique and personalized items. Popular projects include:

- RC vehicles and drones

- Custom tool handles

- Wood inlay art

- Mechanical puzzles and toys

- Model airplanes and trains

Benefits of CNC Machining

There are many reasons why CNC machining is preferred in modern manufacturing:

- Precision: CNC machines can produce parts with extremely tight tolerances.

- Efficiency: Automated processes reduce cycle times and increase throughput.

- Repeatability: Each part produced is consistent and identical to the original design.

- Material Flexibility: CNC machines can cut a wide range of materials.

- Complex Geometry: Advanced machines can produce intricate 3D shapes.

- Low Waste: Optimized cutting paths and exact material removal reduce waste.

Conclusion

CNC machines are powerful tools that can produce an astonishing variety of parts and products. Their precision, speed, and adaptability make them essential in industries ranging from aerospace and medicine to furniture and fine art. Whether you are building an aircraft component, a custom tool, a piece of jewelry, or a functional prototype, CNC machining offers the precision and consistency needed to bring ideas to life.

By understanding what CNC machines can do and the materials they work with, engineers, manufacturers, hobbyists, and artists can push the boundaries of creativity and efficiency. With the right tools, software, and imagination, the possibilities are virtually endless.