Computer Numerical Control (CNC) machines have revolutionized modern manufacturing. These machines use computer software to control tools and equipment, allowing for precise and repeatable manufacturing processes. From automotive parts to aerospace components, CNC machines play a critical role in producing complex parts with tight tolerances.

As technology advances, the demand for CNC machines continues to grow. In 2025, understanding the cost of a good CNC machine is crucial for manufacturers, engineers, and business owners planning investments or upgrades. This article offers a comprehensive look into the factors affecting CNC machine costs, the price ranges for different types of machines, and what defines a “good” CNC machine in today’s market.

What Defines a “Good” CNC Machine in 2025?

A “good” CNC machine is one that meets or exceeds the needs of the user, offering reliability, precision, and efficiency. The definition varies based on application, but several key qualities are universal:

- Precision and accuracy: The machine must consistently produce parts within specified tolerances.

- Durability and build quality: Quality materials and construction reduce downtime and maintenance.

- Ease of use: Intuitive control software and ergonomic design improve operator efficiency.

- Versatility: Ability to work with various materials and perform multiple functions.

- Support and service: Access to technical support, training, and replacement parts is vital.

Types of CNC Machines and Their Cost Ranges

CNC machines come in several types, each suited to different manufacturing needs. The cost of these machines depends heavily on their complexity, size, and capabilities.

CNC Milling Machines

CNC milling machines are among the most common. They remove material from a workpiece using rotary cutters to create parts with complex shapes.

- Entry-level models suitable for hobbyists and small workshops typically start at $10,000 and can go up to $50,000. These machines are smaller and less powerful but still capable of producing detailed parts.

- Mid-range milling machines intended for professional manufacturing range from $50,000 to $150,000. They offer larger work envelopes, higher speeds, and advanced control systems.

- High-end milling centers, often used in aerospace and automotive industries, can cost $150,000 to $500,000 or more. These machines feature multiple axes, high precision, and automated tool changers.

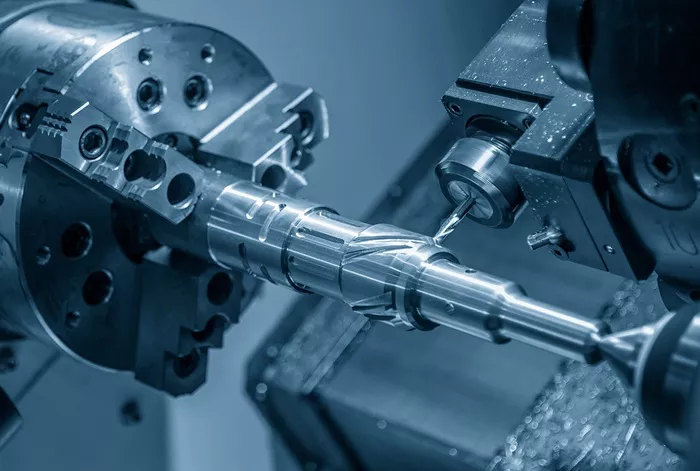

CNC Lathes

CNC lathes rotate the workpiece while cutting tools shape it, ideal for cylindrical parts.

Entry-level CNC lathes cost between $15,000 and $60,000. Mid-range models generally fall in the $60,000 to $200,000 bracket. High-end, multi-axis lathes with live tooling and sub-spindles can exceed $300,000.

CNC Plasma Cutters

Used primarily for cutting sheet metal, CNC plasma cutters vary widely based on size and power.

Small desktop models start around $5,000, while industrial machines for thick metal cutting can cost from $50,000 to $200,000 or higher.

CNC Routers

CNC routers are often used for woodworking, plastics, and soft metals.

Entry-level routers can cost as little as $8,000. More robust, industrial-grade CNC routers usually range from $30,000 to $100,000.

5-Axis CNC Machines

5-axis CNC machines offer advanced movement, allowing for complex parts to be produced with fewer setups.

These machines are more expensive due to their complexity. Prices typically start at $150,000 and can go well beyond $700,000 for large, high-precision models.

Factors Influencing CNC Machine Costs in 2025

The cost of a CNC machine is not fixed and depends on several factors that manufacturers and buyers should consider carefully.

1. Machine Size and Work Envelope

Larger machines that can handle bigger parts or multiple components at once cost more. The physical size impacts material costs, transportation, and installation complexity.

2. Number of Axes

Basic CNC machines have 3 axes (X, Y, Z). Machines with 4, 5, or even more axes offer greater flexibility and precision but increase costs significantly.

3. Spindle Power and Speed

Higher spindle power allows machining harder materials and faster cutting speeds, raising the price. Some industries require very high RPM and torque, impacting machine design.

4. Control Systems and Software

Advanced CNC controllers with user-friendly interfaces, networking capabilities, and compatibility with modern CAD/CAM software add to the cost. Subscription models for software are becoming more common, adding ongoing expenses.

5. Automation and Tooling

Automatic tool changers, robotic loading systems, and integrated measuring probes improve productivity but add to initial investment.

6. Brand and Support

Reputable brands with strong service networks typically charge more, but their machines often last longer and have less downtime.

Additional Costs to Consider Beyond the CNC Machine Price

Purchasing the CNC machine is only part of the total investment. Other costs can be significant.

Installation and Setup

Proper installation requires skilled technicians and can cost thousands of dollars. Machine leveling, alignment, and calibration are critical steps.

Training

Operators and programmers need training to use CNC machines effectively. Training can be onsite or remote, with associated costs depending on complexity.

Maintenance and Consumables

Routine maintenance extends machine life and prevents breakdowns. Consumables such as cutting tools, coolant, and lubricants add ongoing expenses.

Software Licenses

CAD/CAM software licenses can be expensive. Some vendors charge annual fees, which must be budgeted for continuous use.

Market Trends Impacting CNC Machine Pricing in 2025

Several market trends influence CNC machine prices and availability in 2025:

Advanced Materials and Additive Manufacturing Integration

Hybrid machines combining CNC machining and 3D printing capabilities are emerging. These systems tend to be costly but offer unique manufacturing advantages.

Increased Demand for Smart Manufacturing

Industry 4.0 drives demand for CNC machines with IoT connectivity, predictive maintenance, and remote monitoring. These features raise upfront costs but improve efficiency.

Supply Chain Challenges

Global supply chain disruptions affect machine component availability and shipping costs. This can increase prices or extend delivery times.

Energy Efficiency

Manufacturers focus more on energy-efficient machines to reduce operating costs. Energy-saving features might increase purchase price but lower total cost of ownership.

How to Choose the Right CNC Machine Within Your Budget

Selecting a CNC machine is a balance between cost, capability, and long-term value. Here are some tips:

- Clearly define your manufacturing needs and tolerances.

- Consider machine flexibility if your production varies.

- Evaluate total cost of ownership, not just purchase price.

- Request demonstrations and references from manufacturers.

- Factor in future scalability and upgrades.

Summary of CNC Machine Costs in 2025

| Type of CNC Machine | Price Range (USD) |

|---|---|

| Entry-Level CNC Milling Machine | $10,000 – $50,000 |

| Professional CNC Milling Machine | $50,000 – $150,000 |

| High-End CNC Milling Center | $150,000 – $500,000+ |

| Entry-Level CNC Lathe | $15,000 – $60,000 |

| Mid to High-End CNC Lathe | $60,000 – $300,000+ |

| CNC Plasma Cutter | $5,000 – $200,000+ |

| CNC Router | $8,000 – $100,000 |

| 5-Axis CNC Machine | $150,000 – $700,000+ |

Where to Find Reliable CNC Machine Vendors in 2025

To purchase a CNC machine, look for established vendors who offer:

- Transparent pricing and detailed specifications

- Comprehensive after-sales support

- Training and consulting services

- Flexible financing options

Some well-known global brands include HAAS Automation, DMG Mori, Makino, and Okuma. For more regional or specialized needs, consider local distributors who understand your market better.

Conclusion

The cost of a good CNC machine in 2025 varies widely depending on type, size, features, and brand. Prices can range from under $10,000 for simple hobby machines to over $700,000 for advanced 5-axis centers. Beyond the purchase price, ongoing costs like installation, training, maintenance, and software must be factored in for a complete picture.

Investing in the right CNC machine requires careful evaluation of your manufacturing requirements, budget, and long-term goals. A well-chosen machine will boost productivity, ensure high-quality output, and provide a strong return on investment.