Computer Numerical Control (CNC) machines have revolutionized the manufacturing and production industries. These advanced tools use pre-programmed software and code to control the movement of machinery, allowing for precision and consistency in various fabrication processes. As technology has progressed, different types of CNC machines have emerged, each suited for specific tasks and industries. Whether it’s for metal fabrication, woodworking, or intricate part prototyping, CNC machines play a vital role.

Here are the 7 primary types of CNC machines, how they work, and where they are most commonly used.

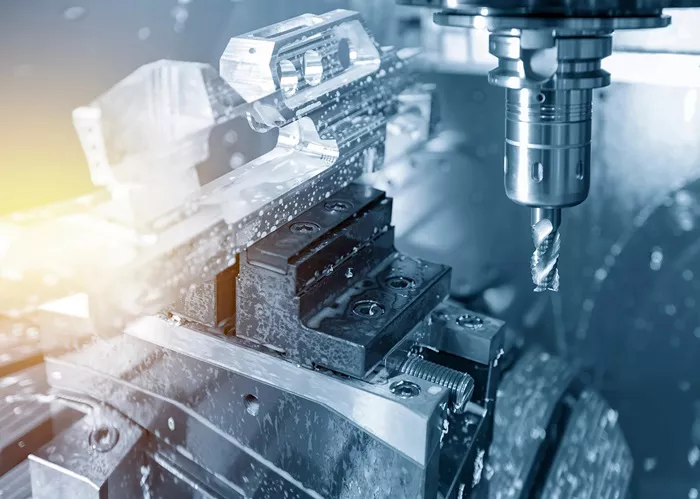

1. CNC Milling Machines

What is a CNC Milling Machine?

A CNC milling machine is one of the most common and versatile types of CNC machines. It uses rotating multipoint cutting tools to remove material from a workpiece. The tool moves along multiple axes to create shapes, holes, and slots with high precision.

How It Works

CNC milling machines operate by interpreting a G-code or M-code program that dictates the movement of the cutting tool. The machine can move the tool along three, four, or even five axes, allowing for complex shapes and designs. These machines typically use vertical or horizontal spindles.

Applications

CNC milling machines are widely used in industries like automotive, aerospace, and electronics. They can create engine parts, molds, dies, and custom-designed components with intricate details.

Benefits

- High precision and accuracy

- Suitable for complex geometries

- Can be used with various materials including metals, plastics, and composites

2. CNC Lathes

What is a CNC Lathe?

CNC lathes are designed for rotating a workpiece against a cutting tool. They are primarily used to create cylindrical parts by removing excess material along the axis of rotation.

How It Works

The CNC lathe operates by spinning the workpiece at high speeds while a fixed cutting tool shapes it. The cutting process is automated, with tool paths defined by the CNC program. Modern CNC lathes can also include live tooling for milling operations.

Applications

CNC lathes are commonly used for producing shafts, pulleys, bushings, and other symmetrical parts. They are essential in metalworking and parts production industries.

Benefits

- High-speed operation

- Exceptional surface finish

- Ideal for producing identical parts in high volumes

3. CNC Plasma Cutters

What is a CNC Plasma Cutter?

A CNC plasma cutter is a machine that uses a high-powered plasma torch to cut through electrically conductive materials like steel, aluminum, and copper. The plasma jet is created by forcing compressed air or gas through a nozzle at high speed while an electrical arc is formed.

How It Works

The CNC software controls the movement of the plasma torch according to the pre-set design. This allows for precise, fast, and repeatable cuts through thick and thin materials alike.

Applications

CNC plasma cutters are popular in the metal fabrication, construction, and automotive industries. They are used to cut custom metal shapes, signs, automotive parts, and industrial components.

Benefits

- Cuts through thick materials quickly

- Precise and clean edges

- Cost-effective for medium to large-scale cutting projects

4. CNC Laser Cutters

What is a CNC Laser Cutter?

A CNC laser cutter uses a focused, high-powered laser beam to cut or engrave materials. The beam is controlled by CNC software, allowing for extremely precise and detailed designs.

How It Works

The laser beam is directed onto the material’s surface, either melting or vaporizing it. CNC laser machines can work with a variety of materials, including metal, plastic, wood, acrylic, and fabric. They often include systems to assist with heat management and smoke extraction.

Applications

These machines are used in industries like signage, jewelry making, electronics, and model building. They are ideal for cutting intricate patterns, etching text, and engraving logos.

Benefits

- Extremely high precision

- Minimal material waste

- Suitable for delicate and intricate work

5. CNC Electric Discharge Machines (EDM)

What is CNC EDM?

CNC Electric Discharge Machining (EDM), also known as spark machining, is a unique process that removes material using electrical discharges or sparks. It is ideal for hard metals or materials that are difficult to machine using traditional methods.

How It Works

EDM machines use a thin wire or electrode that creates a series of sparks between it and the workpiece, gradually eroding the material. This process is guided by CNC programming for exacting shapes and finishes.

Applications

CNC EDM is heavily used in the mold-making and tool-making industries, especially for producing intricate cavities and fine details. It’s also useful for parts requiring sharp corners or tight tolerances.

Benefits

- Suitable for very hard materials

- Achieves high surface finish

- Can produce complex shapes that are difficult with traditional machining

6. CNC Routers

What is a CNCRouter?

A CNC router is similar to a CNC mill but is generally used for softer materials and large-scale production. These machines are particularly popular in woodworking, plastics, and light metals.

How It Works

The CNC router cuts along X, Y, and Z axes by following programmed tool paths. Unlike manual routers, CNC routers offer automation and repeatability, which reduces labor and increases efficiency.

Applications

CNC routers are widely used for furniture production, cabinetry, sign making, and 3D carvings. They can also be used to produce parts for musical instruments and architectural details.

Benefits

- Ideal for high-volume production

- Cost-effective for non-metal materials

- Enables complex carving and engraving

7. CNC 3D Printers

What is a CNC 3D Printer?

Though not a subtractive process like other CNC machines, CNC 3D printers fall under the CNC category because they are controlled by programmed instructions. They build parts by adding material layer by layer, usually using plastic filament, resin, or metal powders.

How It Works

CNC 3D printers follow a digital model file (like STL or OBJ), which is sliced into layers. The machine then extrudes or fuses material layer-by-layer until the final object is formed.

Applications

3D printers are used in prototyping, product development, and even end-use part manufacturing. They are common in sectors such as aerospace, healthcare, automotive, and education.

Benefits

- Allows rapid prototyping

- Minimal material waste

- Capable of creating complex, organic shapes

Choosing the Right CNC Machine

Understanding Your Needs

Choosing the appropriate CNC machine depends on several factors:

- Material type: Some machines are better suited for metals, while others are ideal for plastics or wood.

- Project complexity: CNC mills and 3D printers handle complex geometries well.

- Production scale: CNC routers and lathes are excellent for high-volume manufacturing.

- Precision level: Laser and EDM machines provide extreme accuracy for delicate or complex components.

Software and Training

All CNC machines require compatible software to convert design files into machine instructions. Popular software includes Fusion 360, Mastercam, and SolidWorks. Proper training is also crucial for safe and efficient operation.

Maintenance and Costs

Maintenance Requirements

CNC machines are long-term investments, but they require consistent maintenance to stay in top condition. Regular checks, cleaning, and lubrication are necessary. Software and firmware updates are also important for performance and security.

Initial and Operational Costs

Initial cost: Varies widely from a few thousand dollars for desktop routers or mills to hundreds of thousands for industrial 5-axis mills or EDM machines.

Operational cost: Includes tooling, maintenance, electricity, and software licensing.

Conclusion

CNC machines are the backbone of modern manufacturing, offering precision, efficiency, and versatility. Understanding the different types—milling machines, lathes, plasma cutters, laser cutters, EDM machines, routers, and 3D printers—can help businesses and individuals choose the right tool for their specific needs.

As technology continues to advance, CNC machines will only become more powerful, affordable, and intelligent. Whether you’re a manufacturer, engineer, hobbyist, or designer, there’s a CNC machine that can help you bring your ideas to life with unparalleled accuracy.