The advancement of manufacturing technologies has revolutionized how complex parts are produced. Among the most transformative innovations is the 5-axis CNC (Computer Numerical Control) machine. This technology offers unparalleled versatility, accuracy, and efficiency in machining operations across various industries, including aerospace, automotive, and medical devices. Understanding the workflow of a 5-axis CNC machine is essential for engineers, machinists, and production managers who aim to optimize productivity and deliver high-quality components.

This article provides a professional and in-depth breakdown of the 5-axis CNC machine workflow, from design to post-processing. It outlines each stage of the process to help professionals streamline operations and leverage the full capabilities of their 5-axis CNC systems.

Understanding 5-Axis CNC Machining

What Is 5-Axis CNC Machining?

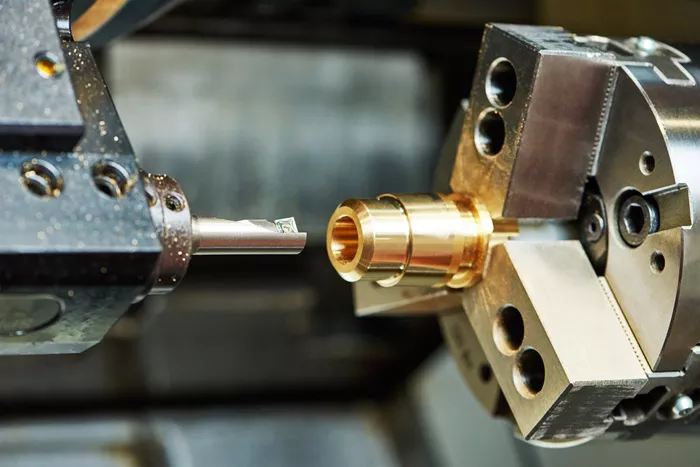

5-axis CNC machining involves the simultaneous movement of a cutting tool or part along five different axes: X, Y, Z (the three linear axes), and two rotary axes (typically A and B or A and C). This configuration allows for the production of complex shapes and features that would be difficult or impossible to achieve with 3-axis or even 4-axis machines.

Advantages of 5-Axis CNC

- Greater part complexity

- Improved surface finishes

- Reduced need for multiple setups

- Shorter cycle times

- Higher precision and consistency

These benefits make 5-axis CNC machining ideal for manufacturing turbine blades, orthopedic implants, engine components, and other intricate parts.

Step 1: Design and Modeling

Concept Development

The first stage in any CNC machining workflow begins with the conceptual design of the part. Engineers and designers collaborate to understand the part’s function, constraints, and performance requirements. This phase often involves feasibility studies and early sketches.

CAD Modeling

Once the concept is finalized, it is translated into a precise 3D digital model using CAD (Computer-Aided Design) software. The model includes every detail—dimensions, tolerances, and geometries—that will be required for machining.

Popular CAD software options include:

- SolidWorks

- AutoCAD

- Siemens NX

- PTC Creo

The CAD model serves as the foundational blueprint for the rest of the manufacturing process.

Step 2: CAM Programming

Toolpath Generation

With the CAD model completed, the next phase involves creating a machining strategy using CAM (Computer-Aided Manufacturing) software. This software generates the toolpaths that the CNC machine will follow to cut the part.

CAM software translates the 3D model into G-code, a series of commands that control tool movement, spindle speed, feed rate, coolant application, and more.

Key considerations during this phase include:

- Selection of cutting tools

- Cutting direction and orientation

- Entry and exit points

- Speed and feed optimization

Machine Simulation

Before running the program on a physical machine, most CAM systems allow simulation of the entire machining process. This is a vital step in the 5-axis workflow, as it helps:

- Detect collisions

- Optimize tool angles

- Validate machine limits

- Improve cycle time estimates

Simulation significantly reduces the risk of costly mistakes and machine damage.

Step 3: Machine Setup

Workholding and Fixturing

One of the unique challenges in 5-axis machining is securely holding the workpiece while allowing for full rotary movement. The setup must be carefully planned to avoid interference during complex tool movements.

Common fixturing solutions include:

- Modular vises

- Vacuum chucks

- Trunnion tables

- Custom soft jaws

A stable and accessible workholding system ensures accuracy and repeatability during machining.

Tool Setup

In this stage, machinists load the appropriate cutting tools into the machine’s tool magazine. Each tool must be:

- Correctly measured for length and diameter

- Matched with the tool numbers specified in the G-code

- Verified for sharpness and wear

Tool offset values are entered into the machine control to ensure precise cuts.

Step 4: Calibration and Zeroing

Machine Calibration

Before machining begins, it’s critical to calibrate the 5-axis machine to ensure that the machine’s actual position matches the programmed coordinates. This involves checking:

- Rotary axis alignment

- Axis backlash

- Spindle runout

- Tool length offsets

Calibration tools such as laser interferometers or probe systems are often used for this purpose.

Setting Work Offsets

Work offsets define the part’s location relative to the machine’s coordinate system. Operators use touch probes or edge finders to set the zero point, commonly at one corner or the center of the workpiece.

Proper calibration ensures that the tool paths align perfectly with the physical part.

Step 5: Machining Operations

Roughing

The first machining pass typically involves roughing, where large amounts of material are removed quickly. The goal is to bring the part close to its final shape while maintaining high material removal rates.

Features of roughing:

- Larger step-over and depth of cut

- High feed rates

- Use of robust cutting tools

- Semi-Finishing

After roughing, semi-finishing operations refine the shape and prepare the surface for the final cut. This step reduces the load on finishing tools and helps achieve consistent dimensional accuracy.

Finishing

Finishing is the most precise machining step, using fine tools and slower feeds to achieve tight tolerances and excellent surface finishes. In 5-axis machines, the ability to tilt the tool enhances surface quality and eliminates the need for post-machining polishing.

Finishing techniques may include:

- Contour milling

- 3D surface machining

- Chamfering and deburring

Step 6: In-Process Inspection

Probing Systems

Modern 5-axis CNC machines often come with in-spindle probing systems. These probes can measure dimensions mid-process and automatically adjust tool offsets, enhancing quality control.

Manual Inspections

Operators may also pause the machining process to manually inspect key features using:

- Micrometers

- Calipers

- Dial indicators

- Surface roughness testers

In-process inspection helps catch errors early and prevents defective parts from progressing through production.

Step 7: Post-Processing and Deburring

Surface Treatment

Depending on the application, machined parts may undergo post-processing treatments, such as:

- Anodizing

- Heat treatment

- Plating

- Sandblasting

These treatments improve wear resistance, appearance, or other mechanical properties.

Deburring

Even the most precise machining can leave behind small burrs or sharp edges. Deburring removes these imperfections, typically using:

- Hand tools

- Abrasive brushes

- Tumbler machines

A clean, finished surface ensures the part is ready for assembly or delivery.

Step 8: Quality Assurance and Final Inspection

Dimensional Verification

Final inspection involves verifying all critical dimensions against the original CAD drawing. This process typically uses:

- Coordinate Measuring Machines (CMMs)

- Optical comparators

- Laser scanners

Dimensional verification confirms the part meets tolerances and specifications.

Documentation and Certification

In regulated industries such as aerospace or medical, comprehensive documentation is required. This includes:

- Inspection reports

- Material traceability

- Compliance certificates

Well-documented quality assurance procedures are essential for maintaining industry certifications and customer trust.

Step 9: Packaging and Delivery

Once a part passes inspection, it is cleaned, packaged, and labeled for shipment. Packaging must be secure to protect the part during transportation, especially for precision components.

Companies may also include:

- Assembly instructions

- Maintenance guidelines

- Customer feedback forms

A smooth end-to-end workflow from design to delivery ensures high customer satisfaction and operational efficiency.

Conclusion

The 5-axis CNC machine workflow is a sophisticated process that combines advanced engineering, skilled craftsmanship, and automated precision. From the initial design to final inspection, each step is critical to producing complex parts with the highest accuracy.

Understanding this workflow empowers manufacturers to:

- Reduce lead times

- Minimize errors

- Improve product quality

- Maximize machine utilization

As industries continue to demand higher precision and faster turnaround, mastering the 5-axis CNC workflow will remain a cornerstone of modern manufacturing excellence.