Siemens and Hirano Tecseed have joined forces to improve battery machine manufacturing. They aim to bring more digital tools and simulation-based optimization into the process.

Hirano Tecseed, a Japanese company that makes battery coating machines, is working with Siemens. Siemens is providing automation and simulation software, including SimcenterTM applications available through its Xcelerator digital platform.

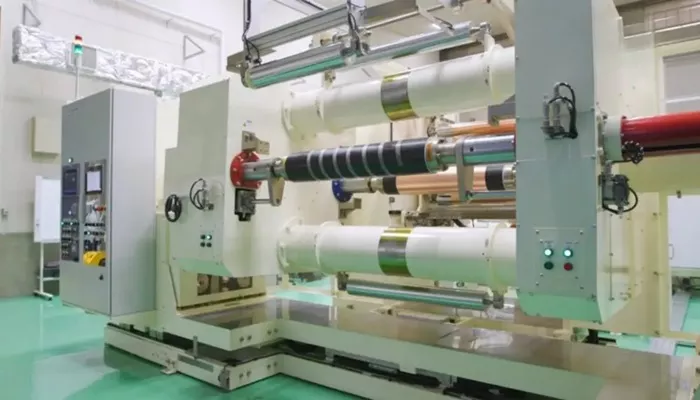

The main focus of this partnership is to optimize the coating process of battery electrodes. This step is very important in battery production. It involves applying several layers of active material onto foil strips. Mistakes in this stage can reduce both the battery’s performance and lifespan. Controlling the speed and tension precisely is essential for producing stable and high-quality batteries.

The push to improve manufacturing comes as global demand for batteries grows. This growth is driven especially by electric vehicles and renewable energy storage. Companies like Hirano Tecseed are working to increase production speed and cut manufacturing costs. At the same time, they want to maintain safety and quality standards.

A key part of this collaboration is the use of a digital twin for the manufacturing equipment. Using Siemens’ SimcenterTM software, Hirano has created a virtual model of its battery coating machines. This digital twin uses real-time data from Siemens’ Simatic controllers and Sinamics drives. This allows accurate simulation of machine performance before actual production begins.

Hirano’s engineers use SimcenterTM AmesimTM for system simulations. This software helps them improve machine designs and increase throughput virtually. It lets design engineers test and adjust important features like web handling to boost efficiency before physical machines are built.

Before adopting this technology, Hirano relied on hands-on experience to set machine parameters. This sometimes led to defects due to less accurate settings. Now, digital twin technology lets the company finalize and check configurations in a virtual environment. This reduces faults and lowers the number of physical prototypes needed during development.

Hirano reports that digital simulations enable engineers to optimize machine settings about five times faster than traditional physical trials. They also say that up to 80% of simulations and virtual commissioning use pre-built standard modules. This simplifies development and cuts costs, speeding up the commissioning of new equipment.

Katsuhiro Omori, Director and Executive Officer of R&D at Hirano Tecseed, said, “We are excited to work with Siemens to improve our battery manufacturing. Combining mechatronics and automation simulation in one model helps us find potential defects early and enhance our processes virtually.”

Michael Thomas, Senior Vice President of Factory Automation and Head of Production Machines at Siemens, added, “Using our advanced simulation and automation technologies, Siemens helps Hirano reach new levels of efficiency and quality in battery production. This partnership shows our dedication to innovation and supporting customers’ digital transformation.”

The companies expect this partnership to shorten implementation and commissioning times, improve product quality, and reduce waste. The ability to simulate and optimize machines digitally before use also saves resources and lowers the chance of problems during production.