Germany’s Volkswagen Group (VW) has been awarded the prestigious Swedish Steel Prize 2025. The prize recognizes their innovative manufacturing method called SIBORA. This method creates new possibilities for improving safety components in vehicles by optimizing crash performance.

Eva Petursson, chair of the Swedish Steel Prize jury and head of research and innovation at SSAB, praised VW and its partners. She said, “VW has developed a press-hardening process that can produce different high-strength and high-ductility properties from a single steel alloy. This patented method offers unique advantages for future car body designs, improving both weight and performance while keeping safety as a top priority.”

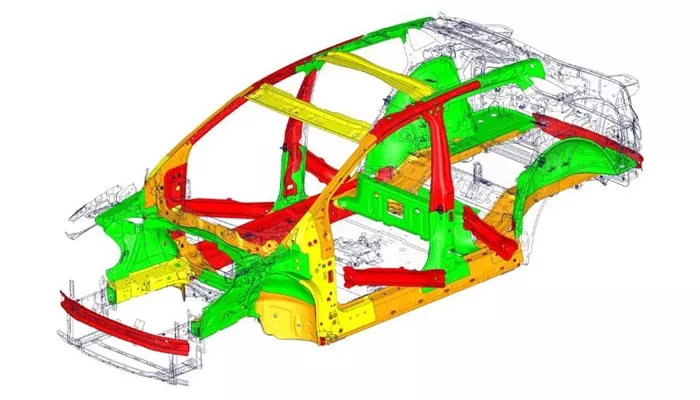

As Europe’s largest car manufacturer, VW aims to become carbon neutral by 2050. A key part of this goal is using less material to build lighter cars. Currently, car components that require different properties—such as areas designed for strength and others for absorbing crash energy—need to be made by welding multiple materials together.

However, the SIBORA method, developed by Dr. Ansgar Hatscher and his team, allows these varied properties to be created from a single sheet of press-hardened steel. The SIBORA alloy delivers both high strength and improved ductility. Its three-step process can be tailored to produce different characteristics in different parts of a component.

VW says that SIBORA will enable faster development of car parts that are stronger, lighter, and better. It also supports a simpler production process, easier assembly, lower costs, and greater sustainability.

The runners-up for the Swedish Steel Prize were The Greenbrier Companies from the USA, InfiniSpring from Finland, and Loglogic from the UK.