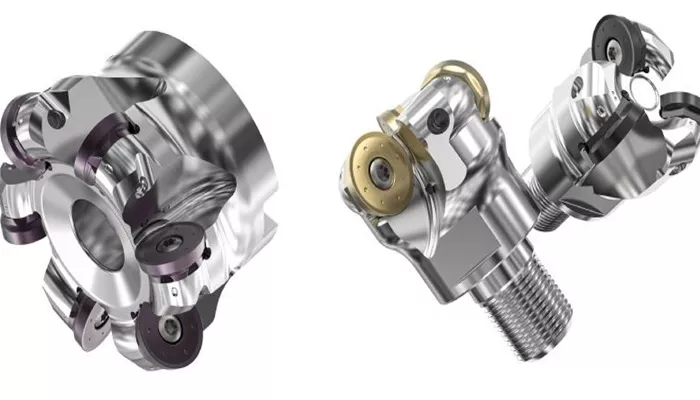

Seco has launched the new generation of Round 20 copy mills and inserts, offering excellent performance across various milling applications. These include face milling, side milling, slotting, plunging, and ramping. The Round 20 inserts fit cutter bodies from earlier generations and provide improved results, especially when working with tough materials.

The new Round 20 cutters and inserts are designed for highly productive medium-to-rough milling in materials such as steel, stainless steel, and heat-resistant superalloys. They can also be used effectively on cast iron and hardened steels. The large-diameter inserts allow for high material removal rates and offer a cost-efficient way to produce R10mm radii using 20mm round inserts.

Benoit Patriarca, Seco’s product manager, said, “This new generation of Round 20 is a major improvement over previous models. The inserts can now be indexed to four, six, or eight positions. This helps users match insert consumption to the depth of cut. It also means the new inserts work with existing cutter bodies that index to four or eight positions.”

Additionally, the use of insert shims and cassettes helps extend the life of Round 20 cutter bodies. These features reduce the risk of damaging insert pockets. They also lower replacement costs and prevent downtime caused by unexpected tool breakage.

The Round 20 range includes 16 cutter bodies, four shim options, three cassette options, and 30 different indexable cutting inserts.