The aerospace sector is under pressure to meet rising production demands while keeping costs down. With major manufacturers like Airbus and Boeing forecasting the need for 42,500 new aircraft over the next two decades, precision machining tools have become more important than ever.

Aircraft construction requires working with a wide range of materials, each with its own machining challenges. Aluminium alloys make up about 60% of aircraft components due to their strength and low weight. Titanium and advanced composites are also used in areas that demand high performance and structural integrity.

Aluminium alloys, especially from the 2xxx, 6xxx, and 7xxx series, are popular for their balance of lightweight and durability. Machining these alloys calls for advanced techniques that ensure accurate shaping, smooth surfaces, and fast material removal. High-speed cutting (HSC) technologies have become essential, and this is where Walter is making major advancements with its latest tool solutions.

Walter’s high-speed cutting tools, including the M2131 and M2331 milling cutters, are designed to tackle the unique challenges of aluminium machining. These tools come with two insert sizes, enabling cut depths of 15mm or 20mm and chip removal rates of up to 11 litres per minute.

The design allows for near-seamless repositioning, creating smooth surfaces even before finishing. A durable PVD coating on the cutting edges improves tool stability and reduces edge build-up. The insert seat is built to handle the strong centrifugal forces of high-speed cutting, while internal coolant channels deliver coolant directly to the cutting edge, increasing tool life and improving chip removal.

Tougher Materials Require Smarter Tools

While aluminium is used in fuselages and wings, titanium alloys such as TiAl6V4 and Ti5553 are chosen for parts needing higher strength—like landing gear, struts, and flap tracks. These alloys are hard to machine because they are tough and don’t conduct heat well. This puts high demands on cutting tools, especially for reliability and wear resistance. Titanium machining often takes more time due to faster tool wear and lower cutting speeds.

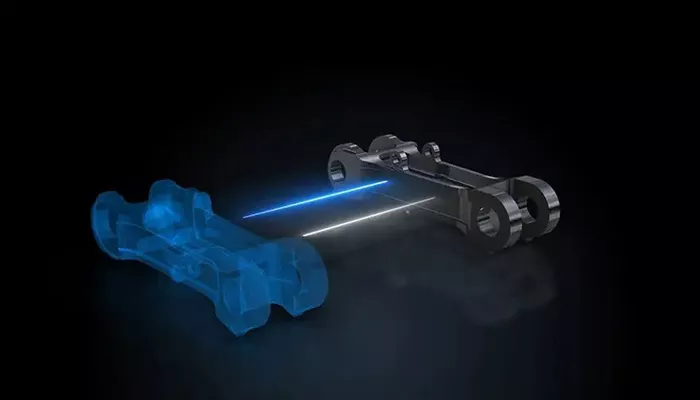

Firms that can reduce machining time gain a clear edge. Walter’s BLAXX M3255 helical milling cutter offers a solution. Its special design allows more cutting edges to engage the material at once. The soft-cutting geometry of the inserts lowers resistance, shortens machining times, and increases metal removal rates.

Because titanium retains heat during cutting, efficient cooling is essential. The BLAXX M3255 has large chip clearance and optimised coolant flow to ensure smooth chip removal even at high speeds. The tangential insert positioning—with two or four cutting edges—gives the tool strong cutting power, even when working on difficult forged surfaces.

Ideal for rough machining, the BLAXX M3255 can cut titanium machining time by about 22% and double the tool life. This is thanks to its smart insert design and improved chip clearance, which boost both material engagement and cutting efficiency.

Meeting the Demands of Heat-Resistant Alloys

Strong demand in aerospace is also pushing engine manufacturers and suppliers to improve how they machine heat-resistant superalloys (HRSA). These materials are tough and slow to cut, so reducing machining time is a top priority. Traditional carbide tools operate at cutting speeds around 50 m/min. In contrast, ceramic cutting tools now allow speeds up to 1,000 m/min—20 times faster—marking a significant leap forward in HRSA machining.