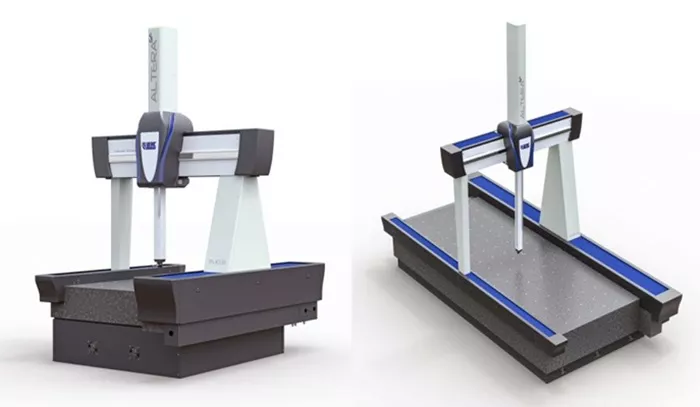

At Control 2025, the international quality assurance trade fair in Stuttgart, LK Metrology unveiled a new range of bridge-type Altera SF Coordinate Measuring Machines (CMMs) designed for industrial environments. These new models offer laboratory-grade accuracy while delivering the performance needed in the rugged conditions of production floors. The eight models, launched this week, promise to enhance inspection processes with faster feedback, increased output, and reduced lead times.

CMMs offer significant benefits over traditional inspection methods that require transporting components to separate quality control (QC) rooms. With on-site inspection, manufacturers can enjoy quicker reporting, rapid adjustments to processes, and fewer risks associated with handling or transporting parts. The result is lower labor costs, higher efficiency, and reduced scrap.

LK Metrology, based in Castle Donington, Derbyshire, designed these CMMs with larger measuring volumes to inspect bulky workpieces close to production. The models feature axis travels ranging from 1,000 x 1,000 x 800mm to 4,000 x 1,500 x 1,500mm. These generous capacities allow for increased operational flexibility, making it easier to meet QC requirements for a wider variety of components.

Features for Precision and Stability

All Altera SF CMMs are equipped with a ceramic bridge and spindle that offer a superior stiffness-to-weight ratio, excellent thermal properties, and long-term stability. Friction drives with air bearings allow for smooth, precise movements, supporting both laser and analogue scanning as well as touch-trigger probing. Users can choose between two probe heads: the Renishaw PH10MQ PLUS indexing probe head or the REVO2 head, which enables five-axis scanning.

One of the key challenges in industrial environments is thermal imbalance, which can affect measurement accuracy. To counter this, the Altera SF models feature a protective cover for the guideways and positive internal air pressure to prevent contamination. Granite tables equipped with fans provide a continuous flow of ambient air to minimize thermal fluctuations. Temperature sensors monitor heat changes within the CMM structure, ensuring that all measurements are compensated to a 20°C reference, regardless of shopfloor temperature changes.

Enhanced Measurement Accuracy

In a significant design shift, the Altera SF CMMs incorporate glass-ceramic optical scales, replacing the stainless steel linear encoders used in other LK models. These scales are immune to thermal expansion and contamination, which helps reduce measurement errors. The low-maintenance scales offer long-term stability and enhanced signal stabilization, resulting in predictable and minimal interpolation errors.

Additionally, the CMMs feature elastomer mounts that isolate them from vibrations and shocks caused by nearby machines. For maximum measurement accuracy, the CMMs can be equipped with active intelligent anti-vibration systems. These systems use magnetic field sensors to detect and automatically adjust for any disturbances in the machine’s position, ensuring stable and precise measurements even in busy production environments.

Automation and Eco-Friendly Features

The Altera SF CMMs are designed for integration with in-line or line-side automation, making them ideal for large volume production. With real-time monitoring capabilities, operators can track machine performance, quality data, and system status via smart devices. An optional EcoAir function helps reduce operating costs by cutting compressed air consumption by 95% during idle periods. Similarly, power to the CMM motors is automatically turned off when the machine is not in use.

All eight models, including versions with varying axis travels (e.g., 10.10.8, 20.12.10, and 40.15.15), come with a 10-year warranty, guaranteeing the accuracy of measurements over the long term.

With these new CMMs, LK Metrology offers manufacturers a robust, high-performance solution for shopfloor quality control that combines precision, durability, and efficiency.