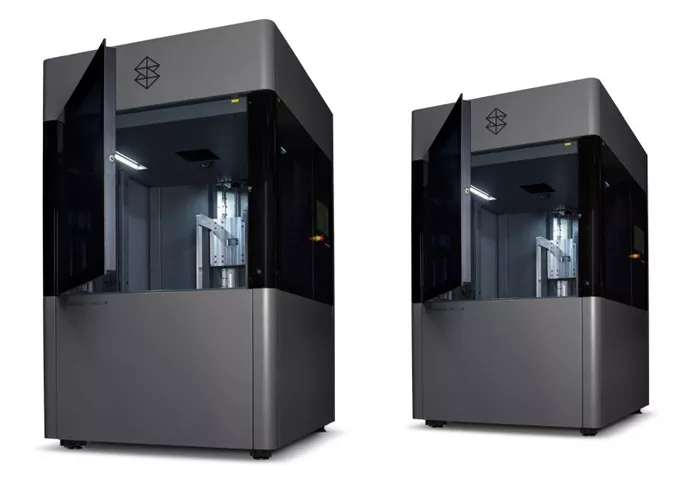

Stratasys Ltd, a global leader in 3D printing solutions, has introduced its latest product, the Neo800+, expanding its stereolithography (SLA) printer range. The new model promises faster 3D printing speeds, higher part yield, and reduced production costs, catering to industries such as aerospace, automotive, consumer products, and healthcare. The Neo800+ is designed to meet the growing demand for applications like wind tunnel testing, prototyping, and tooling.

The company explains that the Neo800+ features ScanControl+, an advanced scanning technology that increases printing speeds by up to 50%. This allows for faster production without compromising on precision. The upgraded laser and optics system ensures high-quality parts with superior surface finish, even when working with high-energy materials.

In practical tests, ScanControl+ has demonstrated a 39% improvement in time-to-part and up to 44% faster production for tooling molds, depending on the materials used. The improved accuracy of the printer also reduces the need for post-processing, leading to lower overall production costs.

Additional features of the Neo800+ include a vacuum system for protection, Z-stage collision detection, and real-time environmental monitoring. These advancements enhance the printer’s reliability and consistency, ensuring high-quality results and better production efficiency.

The Neo800+ is compatible with “ScanControl+ ready materials” from Somos, including the new Somos WaterShed XC+. This material is specifically engineered for the Neo800+, offering faster scan speeds and producing optically clear parts with a smooth finish, while maintaining part quality. It is a next-generation resin, building upon the widely used Somos WaterShed XC 11122.