Narvik Developments Ltd, based in Oldbury, is a well-established manufacturer of moulds, tools, and patterns. With a growing customer base spanning automotive, aerospace, and general subcontract sectors, the company emphasizes the importance of speed in its operations.

Gavin Lee, the works manager at Narvik, explained, “It’s all about shifting metal. The faster you can complete a job, the better. Right now, we are turning over projects approximately every two months, and we handle a variety of work. Over the last 30 years, we’ve built a strong reputation in remanufacturing press tools. We’ve also made substantial investments in our infrastructure, enabling us to handle workpieces weighing up to 10 tonnes. We now have two machine shops running at full capacity, and at this pace, it’s essential that our suppliers help us address challenges quickly.”

One key partnership that has become increasingly important to Narvik is with MSC Industrial Supply Co UK, a supplier of metalworking tools, safety equipment, and maintenance, repair, and operations (MRO) products. In 2022, MSC supplied Narvik with items like safety boots and ground flat stock. However, over time, MSC has become a vital tooling supplier for the company’s 11 metal-cutting machines.

Lee said, “I’ve developed a strong working relationship with Mark Evans, MSC’s territory account manager. If I share a machining issue, I know he will provide the right tools to solve it. Even if the job is particularly challenging, MSC connects me with the right suppliers to get the job done.”

MSC Edge: A Solution for Narvik’s Tooling Needs

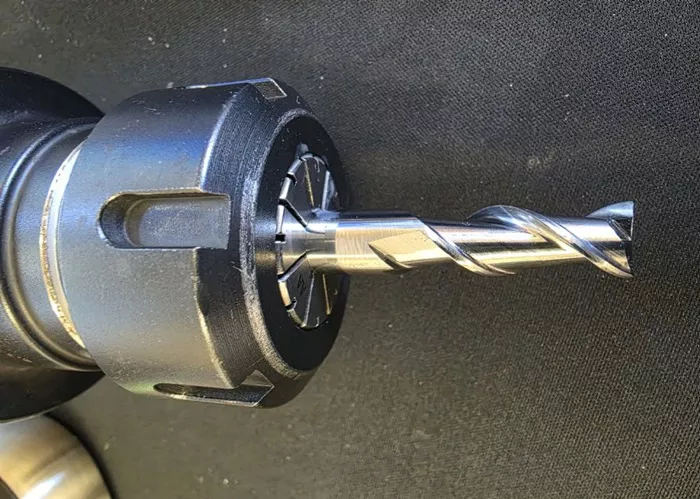

Narvik’s wide range of tooling challenges caught the attention of MSC, which soon selected the company as a test site for MSC Edge, a new line of multi-purpose cutting tools developed by MSC engineers. Over several weeks, MSC’s engineering team conducted trials on various materials and tool paths to identify the best tooling solution for Narvik. These trials also served as a critical data-gathering phase ahead of the official launch of MSC Edge.

After completing the trials, Narvik received a selection of solid-carbide hole-making and milling tools. Lee shared, “We’ve been working with aerospace aluminium, which is quite abrasive. These tools have performed excellently over several weeks, maintaining their sharpness. We were able to use them right away with minimal adjustments. There was no need to alter the feeds or speeds; we simply loaded them into the machine and pressed start.”

Mark Evans from MSC added, “The work Narvik is doing reflects a broader trend in the precision engineering industry. Companies are taking on more contract work across various sectors. While this creates more opportunities, it can also lead to higher tooling costs. One of the goals behind developing MSC Edge was to help engineers like Gavin optimize their tooling costs.”