Industrial automation leader Fanuc UK has partnered with Reeco Automation to enhance its RB palletiser series with Fanuc’s CRX collaborative robots (cobots). The move comes as manufacturers, especially in food and beverage, struggle with labor shortages and seek automated solutions for end-of-line tasks.

Easier Automation for SMEs

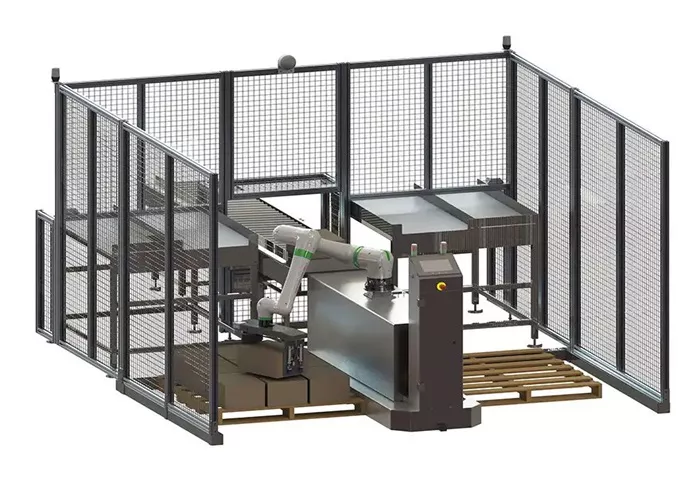

Reeco’s RB Palletiser systems automate manual loading, a role increasingly difficult to staff. By integrating Fanuc’s CRX-20iA (20kg payload) and CRX-30iA (30kg payload) cobots, the companies aim to make automation more accessible—particularly for small and mid-sized businesses. The cobots promise efficiency gains, energy savings, and lower operational costs.

Fanuc’s CRX series is known for safety, ease of programming, and minimal maintenance, backed by warranties of up to five years. Reeco’s RB systems, already popular for their compact design and quick integration, will now leverage Fanuc’s reliability.

A Strategic Partnership

Rosie Davies, Managing Director of Reeco Automation, said: “Fanuc is a trusted name in automation, and their cobots align perfectly with our RB range. This collaboration strengthens our export strategy and gives customers even greater confidence in our systems.”

Oliver Selby, Fanuc UK’s Head of Sales, noted the timing fits industry trends: “With UK food and beverage automation growing fast, cobots help address labor shortages while freeing workers for higher-value tasks. Partnering with Reeco ensures more businesses, including SMEs, can adopt this technology.”

Seamless Integration and Trials

The companies have worked closely to ensure smooth cobot integration into Reeco’s RB systems. A demo unit featuring the Fanuc CRX cobot is now available for free trials at Reeco’s Newtown, Wales, headquarters.

For manufacturers seeking efficient, cost-effective palletising, the Fanuc-Reeco collaboration offers a compelling solution.