Siemens has introduced its Machinum CNC digitalization software portfolio to help machine tool users and builders improve productivity. The software allows seamless integration, enabling better management, analysis, and optimization of shop floor performance.

Seamless Integration for Digital Transformation

The Machinum portfolio is part of Siemens’ Xcelerator platform, helping manufacturers speed up digital transformation. It supports energy efficiency, sustainability, and high-quality production. The technology works not only with Siemens’ Sinumerik-controlled CNC machines but also fits into any existing manufacturing setup.

Three Key Solutions for Smarter Manufacturing

The portfolio is divided into three main solutions:

- Smart Machine – Uses real-time data to cut programming and material costs while improving machine uptime and machining speed.

- Smart Shopfloor – Reduces operational costs and boosts efficiency by optimizing pre-production planning and resource management.

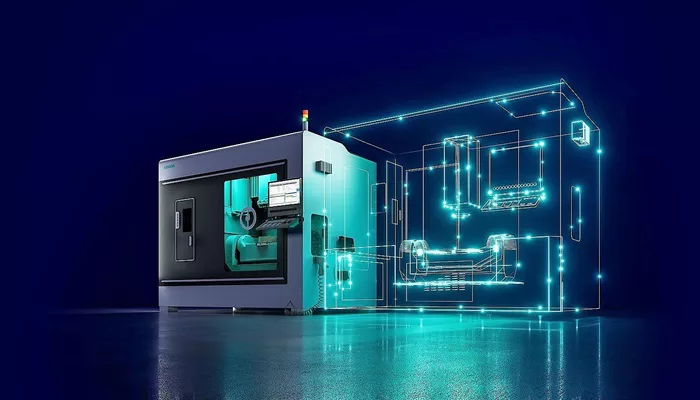

- Smart Virtual Machine – Incorporates digital twin and closed-loop engineering to lower programming costs and enhance machine performance.

Boosting Speed and Reducing Downtime

The Smart Virtual Machine feature allows companies to test processes virtually using digital twin technology. This helps speed up new part production and minimizes costly machine downtime.

Cutting Machining Time by 15%

The portfolio includes Adaptive Control and Monitoring (ACM), which Siemens says can reduce machining time by up to 15% and prolong the lifespan of cutting tools.

This new software suite aims to make manufacturing faster, more efficient, and adaptable to industry demands.