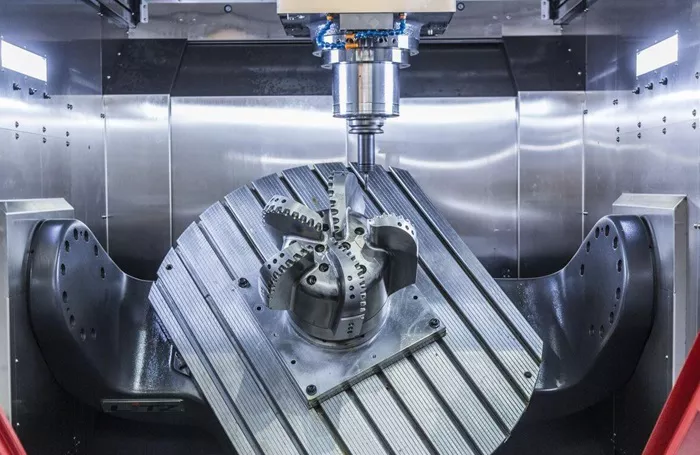

5-Axis CNC machining is a cutting-edge manufacturing process that has transformed the way complex parts are created. It involves the simultaneous movement of a cutting tool along five different axes, allowing for the production of intricate components with exceptional precision and surface quality. This advanced method surpasses traditional 3-axis machining by adding two additional rotational axes, enabling the tool to approach the workpiece from virtually any direction.

The adoption of 5-axis CNC machining spans a wide range of industries, including aerospace, automotive, medical, and mold making. Its capabilities address the challenges posed by complex geometries, tight tolerances, and the demand for efficient, high-quality production.

Understanding CNC Machining Fundamentals

CNC, or Computer Numerical Control, refers to the automation of machine tools via programmed instructions. A CNC machine interprets these coded commands to control the movement of cutting tools and the workpiece. Traditional CNC machining typically operates on three linear axes: X (left to right), Y (front to back), and Z (up and down).

In contrast, 5-axis CNC machines incorporate two additional rotational axes, often labeled A and B (or B and C), which rotate the tool or the workpiece. This configuration allows for complex machining strategies, including angled cuts and contoured surfaces that are difficult or impossible to achieve with 3-axis machines.

Detailed Explanation of 5-Axis CNC Machining

The Five Axes Defined

The five axes consist of:

- X-Axis: Linear movement horizontally, left to right.

- Y-Axis: Linear movement horizontally, front to back.

- Z-Axis: Linear movement vertically, up and down.

- A-Axis: Rotational movement around the X-axis.

- B-Axis: Rotational movement around the Y-axis.

Some configurations use the C-axis, which rotates around the Z-axis. These additional rotational movements enable the cutting tool to be positioned at virtually any angle.

Machine Configurations and Their Functions

5-axis CNC machines are typically built in one of three configurations:

- Table-Table Configuration: Both rotational axes are on the worktable, allowing the workpiece to rotate and tilt.

- Head-Table Configuration: One rotational axis is on the tool head, and the other is on the worktable. This configuration offers a balance between flexibility and stability.

- Head-Head Configuration: Both rotational axes are on the tool head, moving the cutting tool itself to achieve complex angles.

The selection of configuration depends on the size of the workpiece, required precision, and machining complexity.

Programming and Operation

Programming 5-axis CNC machines is more complex than 3-axis machining. It requires sophisticated CAM (Computer-Aided Manufacturing) software that generates multi-axis toolpaths. These programs coordinate the simultaneous movement of all five axes, ensuring collision avoidance and maintaining optimal cutting angles.

Operators must validate toolpaths through simulations before machining to avoid costly mistakes. Proper programming enhances machining efficiency, surface finish, and tool life.

Advantages of 5-Axis CNC Machining

1. Ability to Machine Complex Shapes

5-axis machining can create intricate and contoured geometries in a single setup. This is essential for industries like aerospace and medical, where parts often have complex curves and tight tolerances.

2. Reduced Setup Time

With 5-axis machines, multiple faces of a part can be machined without repositioning the workpiece. This reduces setup time and lowers the risk of errors associated with re-clamping.

3. Enhanced Precision and Surface Quality

The continuous adjustment of tool angles enables superior surface finishes and greater dimensional accuracy. This minimizes the need for manual finishing and rework.

4. Extended Tool Life

Maintaining optimal cutting angles reduces cutting forces and distributes wear evenly across the tool. This prolongs tool life and reduces tooling costs.

5. Increased Production Efficiency

By machining multiple features in one operation, production cycles are shortened. This leads to higher throughput and lower manufacturing costs.

Applications of 5-Axis CNC Machining

Aerospace

Aerospace components such as turbine blades, structural brackets, and engine parts demand high precision and complex shapes. 5-axis CNC machining meets these requirements by producing parts with tight tolerances and superior surface finishes.

Automotive

In the automotive industry, 5-axis machining is used for prototyping, custom parts, and molds. It allows for rapid production of parts with complex geometries, contributing to faster development cycles.

Medical

Medical implants and surgical instruments often require unique shapes tailored to patient anatomy. 5-axis machining offers the flexibility and precision needed for manufacturing such customized devices.

Tool and Die Making

The production of high-precision molds and dies benefits from 5-axis machining, which can produce detailed features and smooth surfaces required for quality final products.

Challenges and Considerations

Initial Investment and Costs

5-axis CNC machines are more expensive than 3-axis alternatives. The investment includes the machine, advanced CAM software, and operator training. However, the long-term benefits often justify the cost for companies with complex manufacturing needs.

Programming Complexity

Effective use of 5-axis machining requires expertise in programming and simulation. Incorrect programming can cause collisions or poor surface quality, leading to scrap parts and downtime.

Maintenance and Calibration

Due to their mechanical complexity, 5-axis machines require regular maintenance and precise calibration. Accurate alignment of the axes is critical to ensure machining precision.

Future Trends in 5-Axis CNC Machining

Advancements in automation, artificial intelligence, and machine learning are driving the evolution of 5-axis CNC machining. Integration with robotic loading, real-time monitoring, and AI-assisted programming is making the process more efficient and less operator-dependent.

Additionally, the development of new cutting materials and high-speed spindles enhances machining performance, allowing for faster production and better surface finishes on hard-to-machine materials.

Conclusion

5-axis CNC machining is a transformative technology that offers unparalleled flexibility, precision, and efficiency in manufacturing. Its ability to machine complex shapes in fewer setups with improved surface finish and accuracy makes it a critical tool for modern industry.

While it requires significant investment and expertise, the benefits in productivity, quality, and capability provide a compelling case for adoption. As technology continues to evolve, 5-axis CNC machining will remain at the forefront of advanced manufacturing, enabling innovation and excellence across multiple sectors.

For manufacturers seeking to meet increasingly demanding product designs and tight deadlines, investing in 5-axis CNC machining is a strategic step toward achieving competitive advantage and operational excellence.