Starrag, a leading German machine tool manufacturer, has introduced a new series of large machines under its Heckert brand. The company revealed the first model during an Open House event in Chemnitz, with three additional models set for release throughout 2025.

Developed by Starrag’s High Performance Machining Systems (HPMS) unit – which operates from Chemnitz and Rorschacherberg – the new series is based on a modular construction system. This approach allows multiple machining centre configurations to be built from a common platform. The new machines are set to replace the long-running Heckert HEC Large Athletic series.

Built on Proven Principles

Starrag has designed the new models using its well-established principles of high rigidity and precision. The machines maintain the same movement sequences as the previous series. This ensures that operators already familiar with the HEC Large Athletic models can transition easily to the new machines. Users can also continue using existing devices and NC programs without modification.

Engineers redesigned the machines with modern technical considerations in mind. Key components like the machine bed and columns were updated for thermal symmetry. This means that when ambient temperatures change, the core structures expand or contract evenly. This behaviour helps maintain accuracy and can be corrected more predictably. Additionally, improvements in chip evacuation between the spindle and the workpiece help reduce the risk of heat transfer to key components.

Enhanced Productivity and Efficiency

The new Heckert machines deliver a clear boost in productivity. One major improvement is the increase in ball screw diameter from 63mm to 80mm, which enhances stiffness and cutting performance. As a result, users can cut more aggressively and reduce cycle times. The machines also move faster, with rapid traverse speeds increasing from 40m/min to 50m/min, which cuts down on idle time.

Another key upgrade is the machine’s footprint. The redesigned layout, including a repositioned energy chain and a more compact chip conveyor system, reduces space requirements by about 20%. This is a major benefit for manufacturers facing high factory floor costs.

The machine can now support payloads of up to 20 tonnes, thanks to further structural enhancements. This opens the door to processing larger and heavier components and serves a wider range of industries. The rear energy console has also been reworked. All serviceable components are now grouped in one location, making maintenance easier.

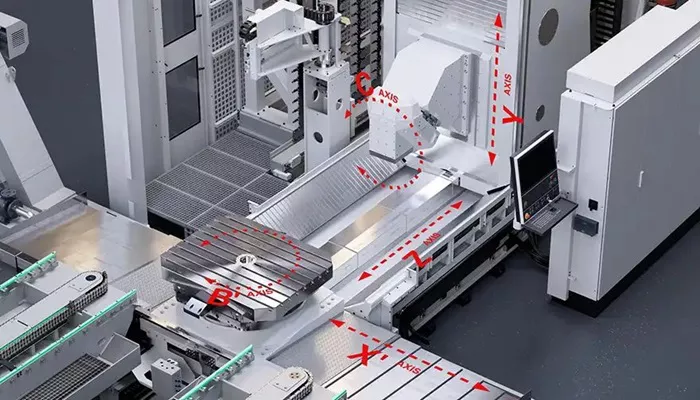

Flexible Modular Design

The new Heckert line comes in four predefined sizes. Each structural element can be freely combined, allowing users to build a machine that suits their specific production needs. The range of spindles and heads is wide and continues to grow. In future versions, users will be able to add attachment heads that allow for varied geometries or different speed settings.

Tool management options have also expanded. Along with existing chain and tower-style magazines, Starrag’s Chemnitz team has developed a new modular rack magazine. It can store up to 828 tools, each up to 380mm in diameter, 1,500mm long, and weighing up to 100kg. The magazine can also handle a tilting moment of 150Nm.

To manage this complexity, Starrag introduced advanced tool management software. It optimises tool arrangement and reserves a dedicated area near the tool changer for quick-access tools. Tools are automatically ejected when they reach the end of their service life. The system also logs all tool intervention times to help with planning and maintenance.