Kingsbury and Additure have been chosen to supply additive manufacturing (AM) technology to the UK Atomic Energy Authority (UKAEA). The UKAEA leads fusion energy research in the UK. It is a national organisation sponsored by the Department for Energy Security and Net Zero.

The UKAEA’s goal is to develop sustainable fusion energy. This energy aims to bring scientific and economic benefits to the UK. Part of their work focuses on building industrial fusion capabilities. They do this by helping manufacturers and supply chains understand the technologies needed to produce fusion energy on a large scale.

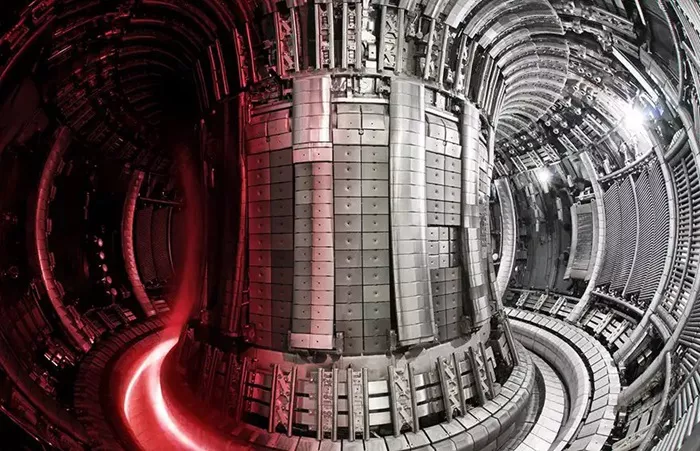

UKAEA has been using Additive Manufacturing, specifically Metal AM, to create parts that can withstand the extreme conditions inside fusion machines. They are also exploring new uses of AM. One example is working with tungsten material layered with other metals like copper.

To support this work, UKAEA has hired Kingsbury and Additure to install a Nikon SLM Solutions SLM®280 2.0 Laser Powder Bed Fusion (LPBF) machine.

Roy Marshall, head of operations for fabrication, installation, and maintenance at UKAEA, said, “Kingsbury and Additure have helped UKAEA develop additive manufacturing for making complex fusion components.”

Supporting UK Industry

Marshall added, “UKAEA wants to promote the commercial use of additive manufacturing. We want to help UK industry transition into the fusion energy sector. We conduct research and development until technologies become commercially viable. The support from our supply chain helps speed up this process.”

Will Priest, business development manager at Additure, expressed his enthusiasm for the project. He said, “We are excited to support UKAEA with the SLM®280’s LPBF technology. We also provide all key elements of the AM ecosystem to create a strong manufacturing solution for UKAEA and the UK fusion programme.”

The SLM®280 2.0 machine helps develop refractory metals and produces parts up to 80% faster than single-laser machines. It includes safety features such as a powder sieve and system cooling to protect operators.

To aid UKAEA’s work, Additure provided extensive training to research, materials, and design teams. This training covered machine setup, optimisation, and use of special features. For example, the heated reduced build volume helps make small batches of powder quickly. This knowledge will support UKAEA’s existing skills.

Mr Marshall concluded, “The training from Additure will help our engineers design the complex structures needed for fusion. It will also allow them to work with some of the toughest materials.”

He added, “For additive manufacturing to help fusion energy, designers need to ask: ‘Which process suits the thermal or structural needs?’ and ‘How can I design for the best AM results?’”