Ingersoll Machine Tools, based in Rockford, Illinois, has delivered a cutting-edge “factory-in-a-box” system to the U.S. Army Corps of Engineers, marking a significant step in the military’s ongoing use of additive manufacturing (AM). The system includes both a 3D printer and a CNC milling machine, all housed in a shipping container, offering a mobile solution for custom hardware production.

Ingersoll has a history of supporting the U.S. military with advanced manufacturing technology. Notably, the company has supplied components for the additive friction stir deposition (AFSD) system at Rock Island Arsenal, home to what is known as the world’s largest metal 3D printer. This latest delivery to the Army follows a successful bid placed two years ago, with the company’s U.S. location playing a key role in the contract’s approval.

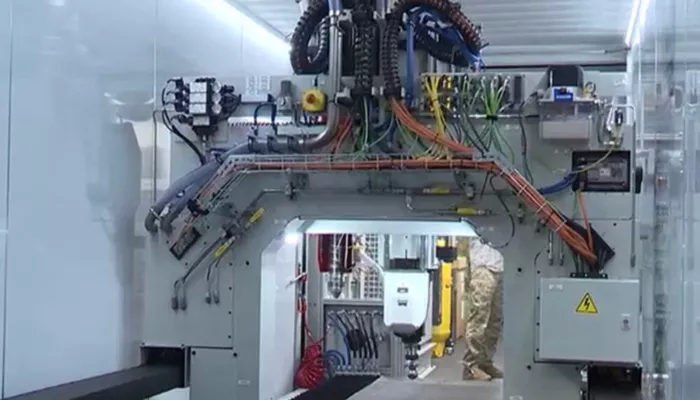

Though details about the new system remain limited, Ingersoll’s VP, Jason Melcher, confirmed to local news outlet WIFR that the machine will be deployed in Illinois. It’s speculated that the system may be a smaller version of Ingersoll’s MasterPrint 3X, a large-format composite 3D printer. If so, the U.S. Army could be exploring ways to produce large thermoplastic parts directly at military sites.

In recent years, the U.S. military has focused on acquiring advanced manufacturing technologies domestically. This is evident in other projects, such as the Chicago-made Additive AMOS printer, which was co-licensed from a NAVWAR patent and announced just weeks ago. Both the AMOS and Ingersoll systems are designed for deployment, indicating their potential use in field operations.

While the AMOS printer appears geared toward drone production, the specific application of Ingersoll’s system remains unclear. However, its delivery to the Army Corps of Engineers, combined with its ability to produce large composite parts, suggests it may be used for construction purposes. This aligns with the Army Corps’ funding of the Construction for Autonomous Manufacturing in Scale (CACMS) program at the University of Illinois, further linking the machine’s capabilities to infrastructure and building projects.