Pratt & Whitney has unveiled a new additive manufacturing (AM) solution designed to repair key components of its GTF engines. This innovation is set to reduce repair times by more than 60%. The company is now focused on industrializing the repair process, with plans to expand its use across the global GTF maintenance, repair, and overhaul (MRO) network. Pratt & Whitney expects to save up to $100 million in part recovery over the next five years by integrating additive repairs into its MRO operations.

Kevin Kirkpatrick, the vice president of aftermarket operations at Pratt & Whitney, emphasized the advantages of the new process. He stated, “The additive repair process allows us to improve turnaround times and lower tooling costs, complexity, and setup. This approach not only reduces reliance on material supply constraints but also has the potential to support the repair of several critical GTF parts. We are exploring more opportunities for its application.”

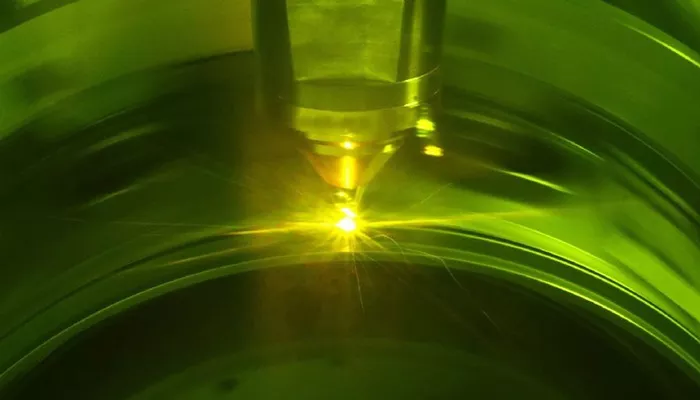

The new solution, developed by Pratt & Whitney’s North American Technology Accelerator in Jupiter, Florida, uses a 3D printing technique called Directed Energy Deposition (DED) to repair structural case features of the GTF engine. This process streamlines several steps of the traditional repair method, cutting overall repair time by more than 60%. The biggest time savings come from reducing machine changeovers and heat treatment cycles.