A major Chinese producer of helical components has placed an order for a high-precision Zenith 400 helical profile grinding machine, built by PTG Holroyd Precision in Rochdale, UK. The machine is set to be installed at the customer’s manufacturing facility in Chongqing later this summer.

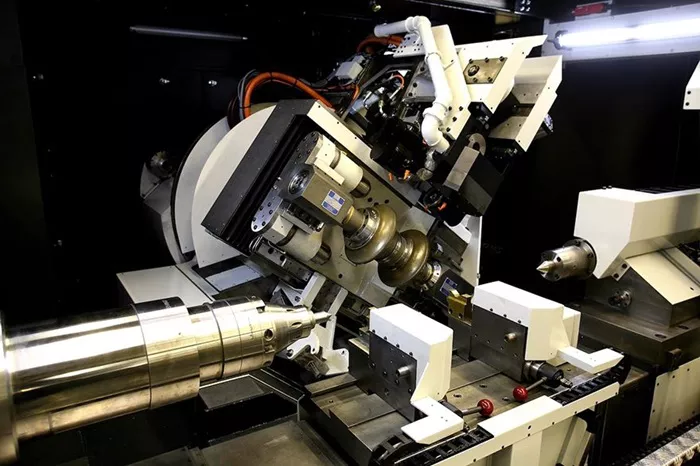

The Zenith 400 is designed for ultra-precise grinding of components up to 700 kilograms in weight, with diameters reaching 420mm, lengths up to 2.2 metres, and profile depths of up to 100mm. The machine is known for its ability to handle high stock removal while also delivering aggressive semi-finishing and fine finishing, making it ideal for demanding manufacturing operations.

A standout feature of the Zenith 400 is PTG Holroyd’s unique dual grinding wheel system. This allows operators to switch between two different types of grinding wheels depending on the production need: a 500mm vitrified aluminium oxide wheel for general versatility, or diamond-hard plated CBN wheels for roughing and finishing in high-volume, cost-sensitive production.

Greater Efficiency in One Setup

Mark Curran, Sales Director at PTG Holroyd Precision, said the dual wheel design was a key selling point.

“With two grinding wheels, the customer can perform both rough and finish grinding in a single operation,” Curran explained. “Using CBN wheels for both stages means shorter cycle times and better heat control. Because CBN is more wear-resistant, there’s also no need for wheel dressing, even with high material removal rates.”

High-Performance Grinding

The order was described as a significant win for PTG Holroyd. Curran added that the Zenith 400’s capabilities and efficiency gains were strong deciding factors for the Chinese customer.

The Zenith 400 is equipped with advanced software that supports both research and development as well as full-scale production. This makes it a flexible solution for a range of industrial applications.

Key features of the Zenith 400 include:

- Options for vitrified aluminium oxide and plated CBN grinding wheels

- Fully automated grinding wheel balancing for faster setup

- Touchscreen programming with a simple menu-driven interface

- High-speed stock removal and precision finishing capabilities

- An integrated 3D CMM scanning probe with automatic compensation

- In-process dressing systems to maintain profile accuracy

- Compatibility with automated parts handling systems

Part of a Global Manufacturing Group

PTG Holroyd is part of Precision Technologies Group (PTG), which also includes PTG Powerstir Friction Stir Welding and Holroyd Precision Rotors. The company is recognised globally for producing high-precision machine tools used in the creation of complex components such as compressor rotors, pump screws, and precision gears.

Holroyd Precision Rotors operates facilities in the UK, USA, and China, manufacturing ultra-precise helical parts for sectors including aerospace, automotive, medical equipment, oil and gas, refrigeration, air handling, and power generation. PTG also offers technical consulting services to support advanced engineering projects.