norelem has expanded its product line with a new compact floating clamp. This clamp is designed and manufactured in-house. It is used for clamping and supporting components at points where multiple clamps may cause over-determination.

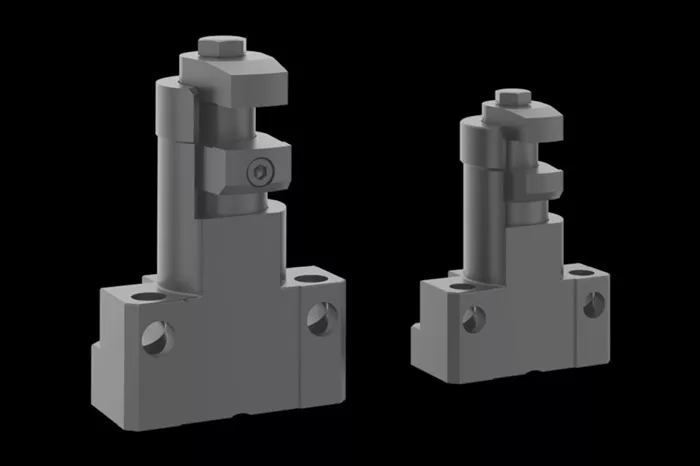

The new floating clamp comes in two versions, offering greater flexibility. The standard clamping jaw can be changed or adjusted to fit different applications.

Floating clamps hold workpieces in place using spring force. At the same time, they allow some movement. This makes them ideal for thin-walled parts that can bend easily. They also reduce vibration and bending during machining. This is especially useful for blanks with fins or parts with complex shapes. The “floating” design provides the needed movement to machine delicate parts accurately. It also helps prevent clamping mistakes.

The new norelem floating clamps come in two types: ‘Form A’ with fixed clamping jaws, and ‘Form B’ with interchangeable jaws. Form A can apply clamping and support forces up to 5,000 newtons. Form B can deliver forces up to 8,000 newtons. Both types have a base made from nitrocarburised steel. The end stops are made of black anodised aluminium.

Using the clamp is straightforward. It is placed under the workpiece by pressing it down. The jaws then swivel into position. The lower jaw touches the bottom of the workpiece. After that, the clamp is secured by tightening a hexagon nut to the correct torque. This ensures the workpiece is firmly clamped and supported.