Air conditioning systems are essential for maintaining comfortable indoor environments, especially in regions with extreme temperatures. The compressor is one of the most critical components of an AC system, often referred to as the “heart” of the unit. It plays a vital role in the refrigeration cycle by compressing refrigerant gas and circulating it through the system to facilitate heat exchange. When it comes to replacing or purchasing a 2-ton AC compressor, understanding the cost factors, technical specifications, and installation considerations is crucial for homeowners, HVAC professionals, and businesses alike. This article provides a detailed, professional overview of the cost of a 2-ton AC compressor, breaking down the factors that influence pricing and offering insights into making informed decisions.

What is a 2-Ton AC Compressor?

Before diving into costs, it’s important to understand what a 2-ton AC compressor is and its role in an air conditioning system. The term “2-ton” refers to the cooling capacity of the AC unit, not the physical weight of the compressor. One ton of cooling capacity is equivalent to 12,000 British Thermal Units (BTUs) per hour. Therefore, a 2-ton AC system can remove 24,000 BTUs of heat per hour, making it suitable for cooling spaces ranging from 900 to 1,200 square feet, depending on factors like insulation, ceiling height, and climate.

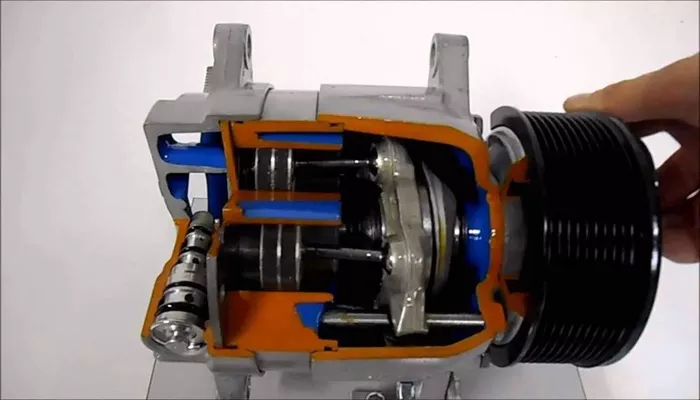

The compressor is the component responsible for pressurizing the refrigerant, which allows it to absorb heat from the indoor air and release it outdoors. Without a functioning compressor, the AC system cannot cool effectively. Compressors come in various types, including reciprocating, scroll, and rotary, each with its own advantages and applications.

Factors Influencing the Cost of a 2-Ton AC Compressor

The cost of a 2-ton AC compressor can vary significantly based on several factors. Below, we explore the key elements that determine pricing:

Type of Compressors

Reciprocating Compressors: These are the most common and affordable type, typically costing between $300 and $600. They are durable and suitable for residential applications but may produce more noise compared to other types.

Scroll Compressors: Known for their efficiency and quieter operation, scroll compressors are more expensive, ranging from $600 to $1,200. They are often used in higher-end residential and commercial systems.

Rotary Compressors: These are compact and lightweight, making them ideal for smaller spaces. Prices range from $400 to $800, depending on the brand and features.

Brand and Quality

The brand of the compressor plays a significant role in determining its cost. Well-known brands like Trane, Carrier, Lennox, and Daikin often charge a premium for their products due to their reputation for reliability and performance. A 2-ton compressor from a premium brand can cost anywhere from $800 to $1,500, while lesser-known brands may offer similar units for $400 to $800.

Energy Efficiency

Compressors with higher Seasonal Energy Efficiency Ratio (SEER) ratings are more energy-efficient but also more expensive. For example, a 2-ton compressor with a SEER rating of 16 or higher may cost $200 to $500 more than a standard-efficiency model. However, the long-term energy savings can offset the initial investment.

Warranty and Durability

Compressors with longer warranties (e.g., 10 years or more) tend to be more expensive. These warranties often reflect the manufacturer’s confidence in the product’s durability and performance. Investing in a compressor with a robust warranty can save money on repairs and replacements in the long run.

Compatibility with Existing Systems

Not all compressors are compatible with every AC system. The cost may increase if additional components, such as a new condenser coil or refrigerant lines, are required to ensure compatibility. It’s essential to consult an HVAC professional to determine the right compressor for your system.

Labor and Installation Costs

The cost of the compressor itself is only part of the total expense. Professional installation is crucial for ensuring proper operation and longevity. Labor costs can range from $500 to $1,500, depending on the complexity of the installation, local labor rates, and whether any additional repairs or modifications are needed.

Geographic Location

Prices for AC compressors and installation services can vary by region. Urban areas with higher living costs typically have higher labor rates, while rural areas may offer more affordable options. Additionally, local demand and availability of specific brands or models can influence pricing.

Refrigerant Type

The type of refrigerant used in the AC system can also impact the cost. Older systems that use R-22 refrigerant (now phased out due to environmental concerns) may require more expensive retrofitting or replacement parts. Newer systems using R-410A or other eco-friendly refrigerants are more cost-effective in the long run.

Average Cost Breakdown

To provide a clearer picture, here’s a breakdown of the average costs associated with purchasing and installing a 2-ton AC compressor:

Compressor Unit: 400to1,500 (depending on type, brand, and efficiency)

Labor and Installation: 500to1,500

Additional Parts (if needed): 100to500

Total Estimated Cost: 1,000to3,500

It’s important to note that these are average estimates, and actual costs may vary based on the factors discussed above.

Why Invest in a Quality Compressor?

While it may be tempting to opt for the cheapest option, investing in a high-quality 2-ton AC compressor offers several benefits:

Energy Savings: A more efficient compressor can significantly reduce energy bills, especially in hot climates where the AC runs frequently.

Longer Lifespan: Premium compressors are built to last, reducing the need for frequent replacements.

Improved Comfort: High-quality compressors provide more consistent cooling and better humidity control.

Lower Maintenance Costs: Durable compressors are less prone to breakdowns, saving money on repairs.

Tips for Purchasing a 2-Ton AC Compressor

Consult an HVAC Professional: A licensed technician can assess your system and recommend the best compressor for your needs.

Compare Quotes: Obtain multiple quotes from reputable HVAC companies to ensure you’re getting a fair price.

Check Reviews and Ratings: Research brands and models online to gauge their reliability and performance.

Consider Long-Term Costs: Factor in energy savings and warranty coverage when evaluating the overall cost.

Verify Compatibility: Ensure the compressor is compatible with your existing system to avoid additional expenses.

Conclusion

The cost of a 2-ton AC compressor is influenced by a variety of factors, including the type of compressor, brand, energy efficiency, and installation requirements. While the initial investment may seem significant, choosing a high-quality compressor can lead to long-term savings and improved comfort. By understanding the factors that affect pricing and working with a trusted HVAC professional, you can make an informed decision that meets your cooling needs and budget. Whether you’re replacing a faulty compressor or upgrading your system, investing in the right 2-ton AC compressor is a decision that will pay off for years to come.