Battery X Metals (CSE: BATX) has announced the successful validation of its next-generation electric vehicle (EV) battery rebalancing technology, marking a major milestone in its development efforts.

Through its wholly owned subsidiary, Battery X Rebalancing Technologies Inc., the company confirmed that key innovations outlined in its provisional patent applications with the U.S. Patent and Trademark Office have been proven effective in preliminary real-world trials.

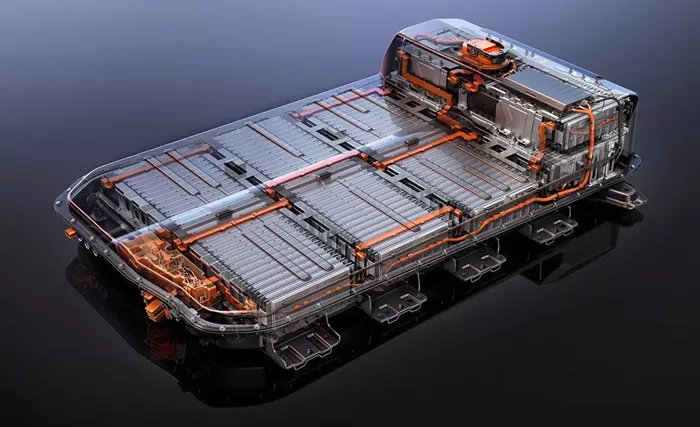

The company’s second-generation platform, Prototype 2.0, was tested on electric vehicle battery packs and showed strong results in restoring lost capacity caused by cell-level imbalances. This advancement supports Battery X’s goal of extending EV battery life and lowering long-term costs for both consumers and commercial fleet operators.

In one test, the system was applied to a 96-cell battery pack from a Nissan Leaf—one of the most widely used EVs now operating without a manufacturer warranty in the U.S. Although the pack showed only minor voltage differences, the system rebalanced all cells to 4.20 volts and recovered 1.95 ampere-hours of capacity. This improvement represents a 3.9% increase in usable energy, showing that the technology works even with relatively healthy batteries.

A second, more demanding trial focused on a 144-cell pack from a fully electric Class 3 commercial vehicle, which showed severe imbalance. In this case, Prototype 2.0 recovered 66.3 ampere-hours, or 37.7% of the pack’s rated capacity. The system was able to restore 100% of the energy lost due to imbalance, confirming its ability to perform under more challenging conditions.

“These trials are confirming exactly what we filed with the USPTO,” said Massimo Bellini Bressi, CEO of Battery X Metals. “Seeing both passenger and commercial EV batteries fully recover capacity lost to imbalance proves that our technology works—and works where it matters most: in real-world conditions.”

Battery X’s platform combines proprietary hardware and software that include advanced diagnostic tools. These tools assess a battery’s State of Health (SoH) and detect degradation patterns. The system is designed to support battery repair and second-life repurposing, which can reduce waste and cut down on replacement costs.

The technology has also been independently verified by the National Research Council of Canada. In controlled testing, Battery X successfully rebalanced a 15-cell lithium iron phosphate (LiFePO₄) module and recovered nearly all the capacity lost due to induced imbalances.

As EV sales hit 17.1 million units in 2024 and with an estimated 40 million vehicles expected to fall out of warranty by 2031, demand for affordable battery maintenance solutions is increasing. Battery X Rebalancing Technologies aims to become a leader in this growing market.

Looking ahead, the company plans to broaden its testing program to include a wider range of battery chemistries and configurations. These efforts are expected to help bring Prototype 2.0 to market for both personal and commercial EV applications.