Researchers in the United States have created a low-cost device using common store-bought tape to generate electricity from human motion and environmental energy. This device, called a triboelectric nanogenerator (TENG), can power small gadgets like wearable health sensors.

TENGs work by converting mechanical energy—such as friction or movement—into electrical energy through the triboelectric effect.

Scientists at the University of Alabama in Huntsville (UAH) designed the generator using commercial materials. They combined metalized plastic films as electrodes with layers of Scotch tape to produce electricity.

The power is generated through interactions between polypropylene and an acrylic adhesive layer when the device is pressed and released. This process creates tiny gaps at the atomic level due to van der Waals forces, which helps generate electricity.

The study, published in the journal American Chemical Society Omega, describes the device as being placed between two plastic plates with a mass on top to create a vibration-based energy harvester.

Dr. Moonhyung Jang, a UAH research scientist, said they tested different types of Scotch tape. “We found some combinations produce even more power than double-sided tape,” he explained. “Because the new TENG only contacts smooth surfaces, we don’t worry about sticky tape surfaces anymore. This allows it to work at very high frequencies—up to 300 Hz.”

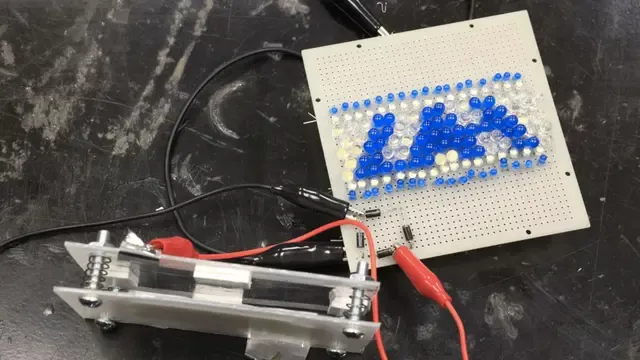

The device can generate up to 53 milliwatts of power, enough to light 350 LED bulbs and a laser pointer. The researchers also integrated the TENG into two sensors: an acoustic sensor that detects sound waves, and a wearable biosensor that tracks arm movements. These biosensors could help monitor muscle activity, potentially preventing injuries and improving athletic performance.

“We will keep exploring new designs and applications,” Jang said. “We have submitted disclosures on energy harvesting and wearable biosensors, and a patent application will follow soon.”

One major challenge with earlier TENG devices was their low operating frequency, typically below 5 Hz. “Our design operates up to 300 Hz, which is a big improvement,” Jang noted. “Generating more power from the environment opens up many more uses for this technology.”